30 Years of Sheet Metal Expertise – Your Trusted Metal Component Solution Partner

Founded in 1991, CMI has over 30 years of experience in precision sheet metal fabrication, specializing in mild steel, stainless steel, and aluminum sheets (1.0–3.0mm thick). We provide one-stop solutions covering laser cutting, CNC bending, welding, and precision assembly. Our parts are widely applied in medical, beauty, automation, kiosk, food equipment, and access systems.

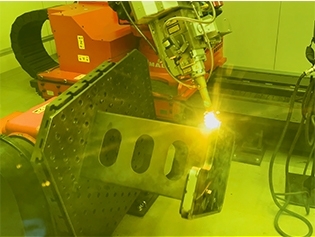

From a humble 55-square-meter workshop to a modern facility equipped with multi-million NTD Amada FLW laser welding systems, we continuously implement advanced manufacturing processes and smart management systems to ensure high efficiency and consistent quality.

With our core principles of Quality First, On-Time Delivery, and Technical Innovation, CMI proudly serves OEM/ODM clients across Taiwan, Japan, North America, Oceania, and Russia — committed to delivering true value through Made in Taiwan quality and professionalism.

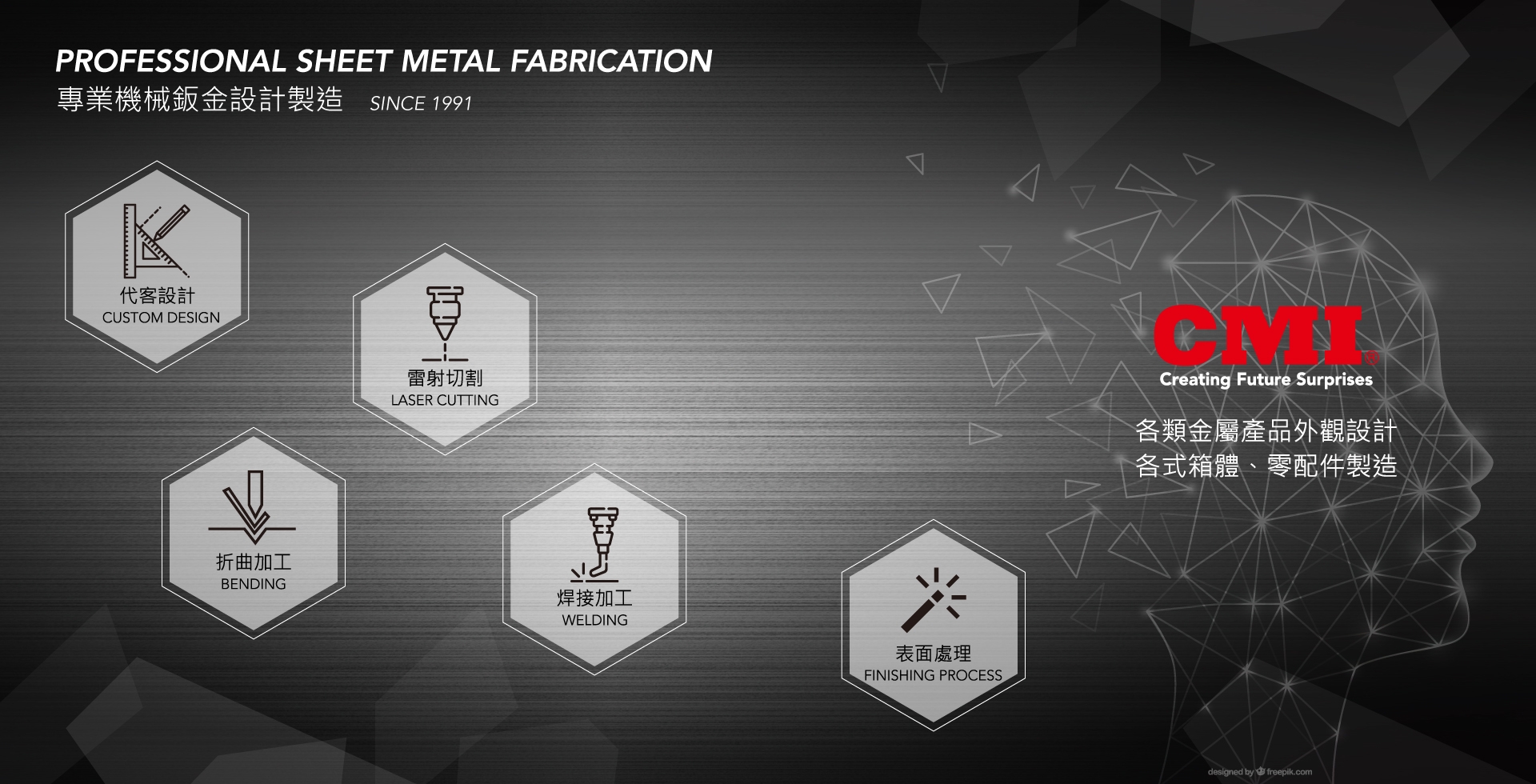

One-Stop Precision Sheet Metal Solutions from Design to Assembly

With over 30 years of experience, CMI specializes in precision sheet metal fabrication, offering end-to-end ODM/OEM services including design, prototyping, mass production, surface finishing, and final assembly. We help clients shorten development cycles, enhance product quality, and accelerate time-to-market.

We work with materials such as steel, stainless steel, and aluminum alloys, supported by advanced laser cutting machines, CNC press brakes, and automated welding systems. Our capabilities are widely applied in industries including medical devices, automation, kiosks, beauty equipment, and access control systems.

- Common Materials: SPCC, SECC, SGCC, SUS304, SUS316, AL5052 — meeting strength, corrosion resistance, and appearance requirements

- Surface Finishes: Powder coating, anodizing, hairline finish, electroplating, sandblasting — tailored to various industry standards and aesthetic demands

Custom Design

We support clients from concept to structural design, delivering tailored metal solutions that meet both functional and mechanical requirements.

Precision Laser Cutting

High-speed laser cutting machines compatible with a wide range of metals, offering excellent processing accuracy and efficiency.

High-Precision Bending

CNC press brakes provide stable angle and dimensional control, ideal for high-volume production and diverse small-lot components.

Professional Welding & Assembly

Utilizing Amada laser welding, TIG, and MIG techniques to ensure consistent weld quality and reduced thermal distortion.